Connections for Innovation | Module Pre-Commercial Procurement | Petrobras | Technology and Inovation

Real and strategic challenges of several Petrobras business areas, which involve:

- Technological risk

- R&D necessity

- No solution on the market

Open Opportunities

Diverless Structural Reinforcement

PETROBRAS is conducting a study on Diverless Structural Reinforcement technology. In the past 2 years, inspections have identified a failure mode in the BNS300 bellmouths, with severe thickness loss near the top of the helmet, caused by abrasion/corrosion. Older bellmouths (19+ years) are vulnerable to failures that affect mechanical strength and can lead to the rupture of the bending stiffener. Petrobras is seeking to develop a structural reinforcement to restore this strength, capable of absorbing lateral forces, without relying on human diving (diverless) or production interruption, with potential application in up to 350 bellmouths.

Closed Opportunities

RFI: USV for autonomous and remote offshore operations

PETROBRAS is carrying out a study on USV FOR AUTONOMOUS AND REMOTE OFFSHORE OPERATIONS and its objective is to obtain information from companies mapped in the Supplier Register or in Market Research, to promote improvements in its supply and specification process.

RFI: Development of Chemical Inputs to Increase Produced Water Injectivity

Petrobras intends to contract the development of specific chemical inputs capable of improving the injection of produced water in secondary oil recovery processes. The application of this type of solution focuses on reducing interventions in injection wells (acidification), increasing or maintaining the injected volume and reducing the pressure differential in the wells during the reinjection process.

RFI: DIVERLESS CONNECTION OF RIGID RISERS IN BELLMOUTHS

PETROBRAS is carrying out a study on DIVERLESS CONNECTION OF RIGID RISERS IN BELLMOUTHS and its objective is to obtain information from companies mapped in the Supplier Register or in Market Research, to promote improvements in its supply and specification process.

RFI: HIGH PRESSURE FLEXIBLE PIPE

Petrobras has been facing several challenges for operational continuity and for the development of new projects - including high internal pressure. To overcome these challenges, it is needed to consider a series of structured actions.

RFI: MECHANICAL CONNECTOR FOR OFFSHORE PIPE JOINT ASSEMBLY

PETROBRAS aims at gathering information on connectors applicable to subsea pipes to enable the construction and installation by a rig or a ship that does not need offshore welding facilities.

MAIN CHARACTERISTICS:

- Connector qualified to operate for 27 years maintenance-free.

- Can be disconnected and reassembled in a new location up to 4 (four) times.

- Redundant and Fatigue-qualified internal metal-to-metal seals, made of corrosion-resistant alloy (CRA) and external environmental metal-to-metal seal. Ideally, the internal seal should be located outside the main load path.

- Comply with or surpass international standards requirements:

DNV-ST-F201:2020 - Riser systems (if applicable);

DNV-ST-F101 Submarine pipeline systems (if applicable)

ISO 13628-7 Completion/workover riser systems

ISO 13679:2019 - Procedures for testing casing and tubing connections.

We are looking for four different pipe functions/scenarios:

a. Water injection, e.g. NACE III + carbon steel on corrosion thickness and PIG campaign every 5 years;

b. Dry gas injection (CO2 + methane with less than 40ppmv of water), e.g. NACE III alloy with corrosion thickness and PIG campaign every 5 years;

c. Wet gas injection with up to 100% CO2, e.g. MLP with CRA liner;

d. Production (multiphase fluid that may contain high levels of water, H2S and CO2), e.g. MLP with CRA liner;

See more

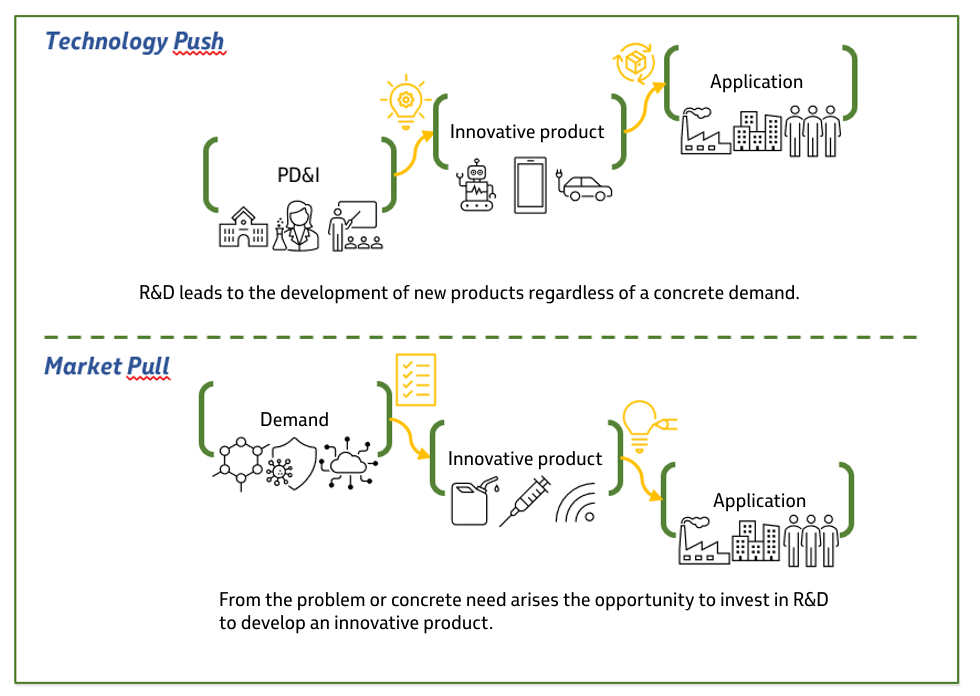

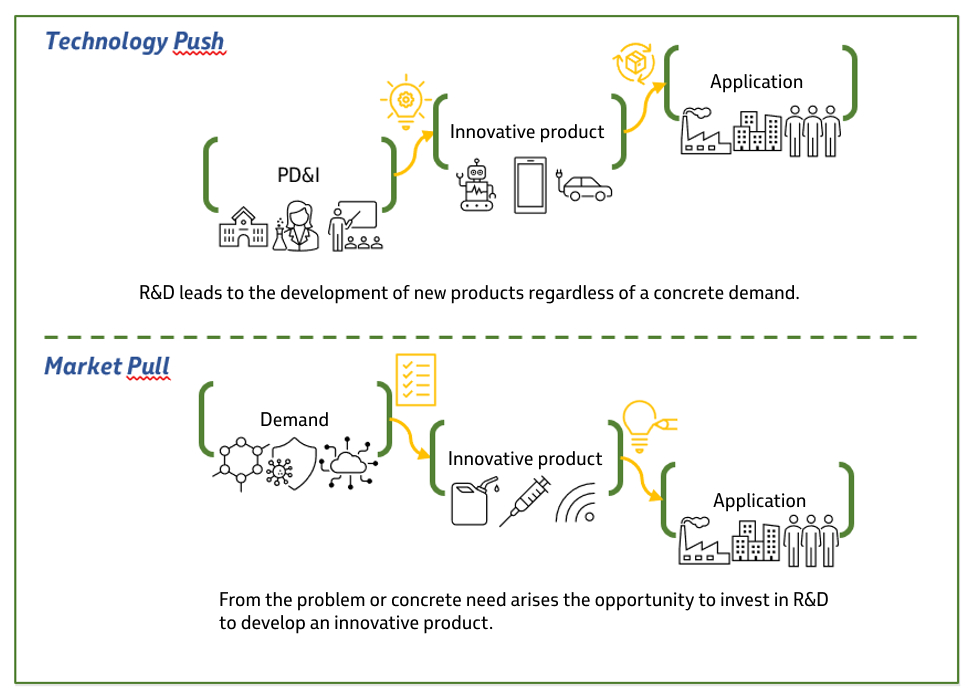

The Pre-commercial Procurement (ETEC) is a special type of public purchase, which does not require bidding, where the objective is to develop a solution that is not yet available on the market and requires a formal R&D effort. The form of innovation is “pulled” by real demand (market pull) and not “pushed” by technology (technology push). ETECs are regulated by Article 29, item XIV of Law No. 13,303/2016; by Article 20 of Law No. 10,973/2004; and by section V of Decree No. 9,283/2018.

By starting from real problems/opportunities, aligned with the interests of the company, which also assumes part of the technological risk and costs, this type of contract manages to make a quick and effective link between the development of the solution and its commercialization, thus mitigating the risks of business for the developer. In this way, the possibility of expanding potential suppliers and expanding Petrobras' RD&I portfolio is envisaged, in addition to accelerating the implementation of innovative technologies.

Among other aspects, ETEC is a contractual modality that brings some innovation incentive devices, such as:

- Possibility of negotiation of intellectual property;

- Inclusion of purchase option clause;

- Different forms of payment ranging from cost reimbursement to fixed price, with or without incentive remuneration (fixed or variable);

The use of one or more of these devices is a characteristic defined in each Pre-commercial Procurement.

See our challenges launched:

Subscribe to Petronect to receive consultation notices

HUBTEC – Channel that centralizes information on Technological Orders HUBTEC – legislation, success stories, good practices, technical content, events, courses and specialized advice from specialists.

Veja nossos desafios lançados

Inscreva-se na Petronect para receber avisos de consultas

HUBTEC – Canal que centraliza informações sobre Encomendas Tecnológicas HUBTEC – legislação, casos de sucesso, boas práticas, conteúdo técnico, eventos, cursos e assessoria especializada com especialistas.